what is the preventive maintenance?

- Preventive Maintenance is a proactive maintenance solution that includes regular and routine maintenance of equipment, machinery, vehicles, and other parts to reduce the possibility of failure.

- This maintenance solution – also referred to as preventative maintenance – consists of scheduled maintenance, cleaning, repairs, and spare part replacements. Ultimately helping businesses to reduce unplanned downtime and extend the life of their equipment.

- If you do not plan a proactive approach to maintenance, maybe when the equipment runs to the point of failure, it will cost you up to 10 times more than the repairs cost.

What is the advantages of preventive maintenance?

1.Reduced cost, product damage

If the companies do not do the prevention maintenance as planned, it will be a very costly move when the problem happens.

2.Longer Asset Life

In general, you will find some minor faults in the equipment when you do effective preventive maintenance. Then you can make some adjustments to avoid damaging your equipment. So effective preventive maintenance can longer assets life.

3. Less Equipment Downtime

- Consider one situation where there are some problems happening to your equipment. What is the total cost you will have to pay?

- The total cost includes overtime for your employees, wasted material, sales chance lost, loss of customers, shipping parts cost and other lost.

4.Improved Safety

Safety is one of the benefits of preventive maintenance. It will cause many dangers, unsafe working conditions, and even workers injured. Preventive maintenance improves the safety of the equipment and the company workers reducing on-the-job injuries and accidents.

5.Increased Equipment Efficiency

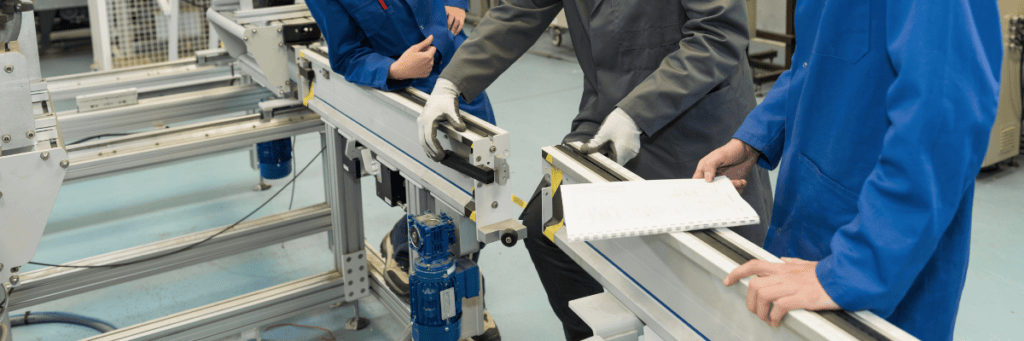

Running efficiency and reducing waste are another benefits of preventive maintenance. Consider one sample as that when you do preventive maintenance for your conveyor systems. It will help you reduce less downtime and the whole production line will perform better. All the parts of the conveyor system can work smoothly and it will help you save energy because your equipment will run at peak performance.

How to Make an Effective Preventive Maintenance Plan?

Effective preventive maintenance can run your production as smoothly and efficiently as possible. Do you know how to make an effective plan for preventive maintenance? Here is a checklist with some tips and tricks that can help you inspect your conveyor system.

- 1. Start with visible surfaces and components examination.

- 2. Do the conveyor chains running as their desired paths ?

- 3. Do the conveyor chains run properly with products?

- 4. Are the conveyor belts and chains clean?

Preventive maintenance can help you schedule maintenance tasks with solutions to keep your equipment in a steady working status.

Companies can operate their preventive maintenance with a checklist to make a plan that can make sure all the equipment and production lines work in their desired ways.