In the dynamic landscape of the beverage and drink industry, efficiency and hygiene are paramount to success. Manufacturers are constantly seeking innovative solutions to streamline their production processes while maintaining the highest standards of cleanliness. One such pivotal component contributing to this synergy is the flexible conveyor chain—a versatile and indispensable tool for material handling.

1. Adaptability in Production Line Configuration

Flexible conveyor chains are engineered to adapt to diverse production line configurations, making them ideal for the ever-evolving needs of the beverage industry. Whether it’s the transfer of bottles, cans, or packaging materials, these chains provide a seamless and customizable solution. Manufacturers can easily modify the layout of their production lines to accommodate changes in product specifications or volume, ensuring a swift response to market demands

2. Gentle and Precise Handling of Fragile Products

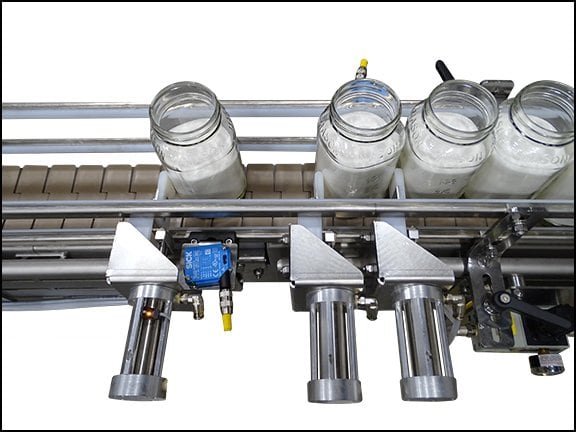

In the beverage industry, where delicate packaging is common, the gentle handling of products is non-negotiable. Flexible conveyor chains, with their modular and low-friction design, minimize the risk of damage to bottles and containers. This not only reduces product waste but also enhances the overall quality of the end product, contributing to customer satisfaction and brand reputation.

3. Easy Sanitization for Stringent Hygiene Standards

Maintaining impeccable hygiene is a top priority in the beverage and drink industry. Flexible conveyor chains are designed with easy disassembly and cleaning in mind. Their materials are often resistant to corrosion and can withstand rigorous cleaning processes, ensuring compliance with industry regulations and providing peace of mind for manufacturers striving for the highest hygiene standards

4. Seamless Integration with Automation Technologies

In an era where automation is transforming manufacturing processes, flexible conveyor chains play a pivotal role in facilitating the integration of cutting-edge technologies. Automated systems can be seamlessly incorporated with these chains, enhancing production efficiency and reducing the need for manual intervention. This not only optimizes workflow but also minimizes the risk of errors in material handling.

5. Sustainability through Energy-Efficient Operation

As sustainability becomes an integral aspect of business practices, flexible conveyor chains contribute by offering energy-efficient operations. Some models are designed with advanced motor systems that consume minimal energy while ensuring maximum performance. This not only aligns with environmental goals but also leads to long-term cost savings for manufacturers.

In conclusion, flexible conveyor chains have emerged as indispensable assets in the beverage and drink industry, revolutionizing material handling processes. Their adaptability, gentle handling, easy sanitization, integration with automation, and sustainability features make them a strategic choice for manufacturers aiming for efficiency, hygiene, and overall excellence in their production lines.

If you’re considering upgrading your material handling system, investing in flexible conveyor chains could be the transformative step your business needs to thrive in the competitive landscape of the beverage industry.