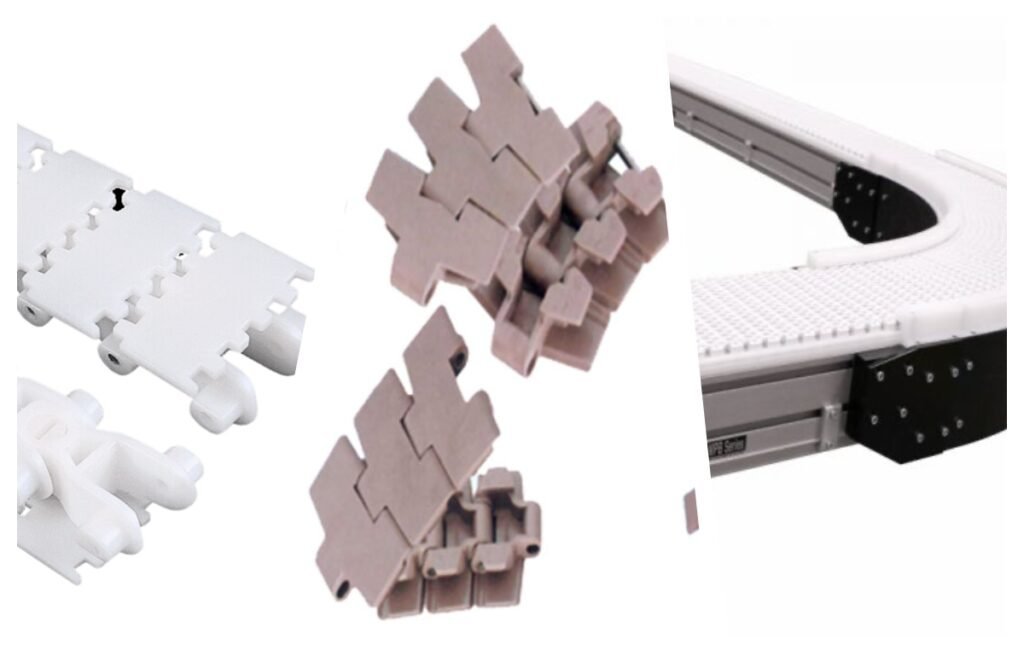

In today’s field of automated transportation, conveyor equipment has been playing a very important role. Conveyor equipment is generally divided into three types, flexible conveyor chain, modular belt, and flat chain. Each type of conveyor chain has its advantages and disadvantages.

Let’s compare flexible conveyor chains, modular belts, and flat chains in the context of your purchasing decision. Here’s a breakdown of their similarities, differences, and respective strengths and weaknesses:

Flexible Conveyor Chain

- Similarities:

- All three products are used in conveyor systems for material handling.

- They are designed for durability and efficiency in transporting goods.

- Differences:

- Flexible conveyor chains are usually made of flexible plastic materials, providing adaptability to the conveyor’s path.

- These chains often excel in applications requiring tight turns and complex layouts.

- Strengths:

- Ideal for conveying products around corners and in tight spaces.

- Resistant to corrosion and wear.

- Weaknesses:

- May have limitations in load-bearing capacity compared to other types.

Modular Belts

- Similarities:

- Shared purpose of conveying materials in a manufacturing or processing setting.

- Differences:

- Modular belts consist of individual modules linked together, offering a flexible and customizable solution.

- Suitable for straight-line conveying and can be adapted for various applications.

- Strengths:

- High load-bearing capacity.

- Versatile and adaptable to different industries and applications.

- Weaknesses:

- May not perform as well in applications requiring tight turns compared to flexible conveyor chains.

Flat Chains

- Similarities:

- Common use in material handling and conveyor systems.

- Differences:

- Flat chains have a simpler design, typically composed of flat metal links.

- Often used in heavy-duty applications where durability is crucial.

- Strengths:

- Excellent for heavy-load applications.

- High resistance to wear and tear.

- Weaknesses:

- May not be as flexible as flexible conveyor chains in terms of navigating tight turns.

Why Choose Our Flexible Conveyor Chain

- Adaptability:

- Our flexible conveyor chain excels in applications requiring flexibility and adaptability in conveyor layouts.

- Corrosion Resistance:

- Our product is designed to resist corrosion, ensuring a longer lifespan and reduced maintenance costs.

- Quality and Durability:

- We prioritize high-quality materials and manufacturing processes, ensuring durability and reliability.

- Customization:

- Our flexible conveyor chain can be customized to meet specific requirements, offering a tailored solution for your needs.

- Technical Support:

- Our company provides excellent technical support and expertise to assist you in optimizing the performance of our flexible conveyor chain.

I hope this comparison helps you make an informed decision! If you have any further questions or need additional information, feel free to ask.