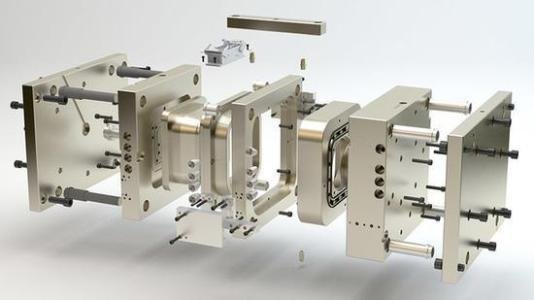

In today’s society, plastic is widely used in people’s economy and all areas of life. The plastic mold has the advantages of small density, high strength, lightweight, good insulation performance, strong chemical stability, and high molding productivity.

Why are injection molds widely used in the plastic processing industry?

The injection mold occupies an extremely vital status in the plastic processing industry. Injection molding is also the most effective molding method for plastic parts because injection molding can be a one-time molding of a variety of complex structures, sizes precision products. Still, it also can achieve metal mosaic, short molding cycle, high productivity, easy to realize automatic production.

What are the advantages and advantages of injection mold?

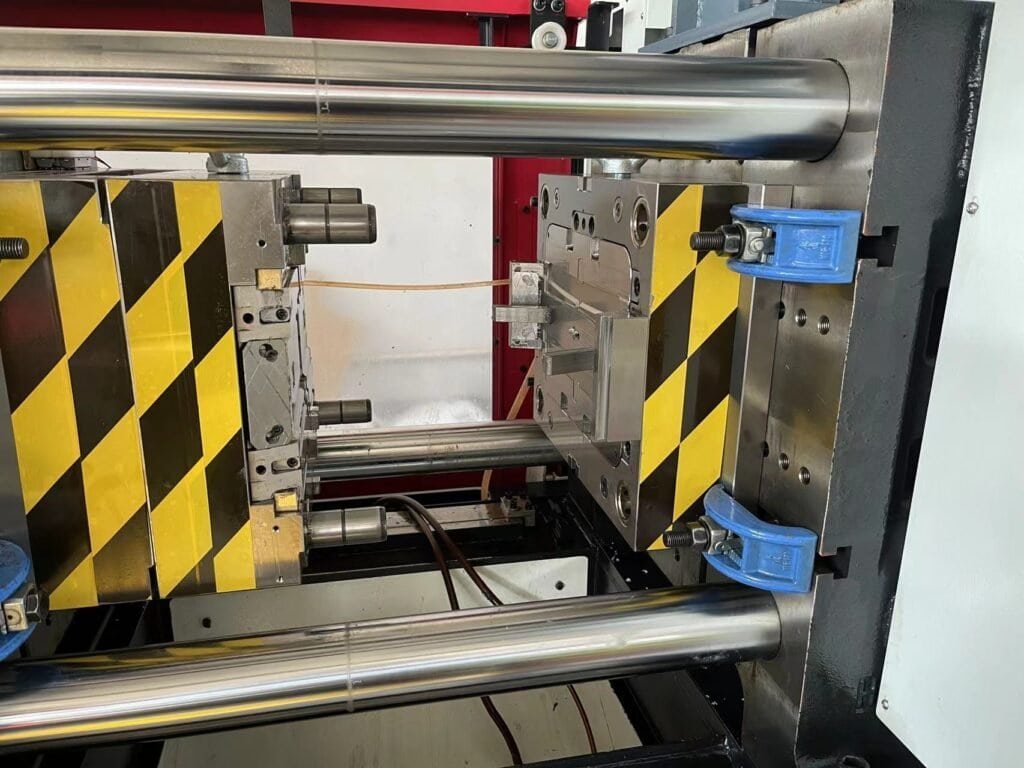

1. Increase productivity

The advantage of injection mold is to improve production efficiency, through mold processing, and can achieve high-speed, high-precision, continuous production, thus greatly improving production efficiency. Compared with traditional manual processing, the mold can achieve automated and semi-automated production, reducing labor costs and working time. The mold has replicability, and can produce the same specification product repeatedly, causing the production process to be more stable and controllable. In addition, the mold can be multi-station, multi-cavity design, to achieve a one-time completion of multiple processes to further improve production efficiency.

2. Ensure product quality

Injection mold in industrial production, to ensure product quality. The injection mold has high precision and stability, the accurate reproduction of product shape size. Through mold processing, eliminates human factors on product quality, and reduces the production error waste. Die manufacturing process strict control and quality inspection to ensure the accuracy and reliability of the die. At the same time, the mold can be through injection mold-casting and other processes to achieve the uniform distribution of materials and density control, improve product physical properties and appearance quality.

3. Reduce production costs

One-time mold manufacturing investment is relatively high, but once the completion of manufacturing can be large-scale, long-term production. The die has a long service life and can be reused many times, thus reducing the waste of raw materials. Compared with the traditional processing method, mold processing can reduce manual operation and energy consumption, improve the utilization of resources, thus reducing production costs. In addition, the mold can reduce the rate of rejected and defective products and further reduce the production cost by optimizing the design and improving the process.

4. Personalize and customize

The injection mold realizes product personalization and customization in industrial production, the mold has flexibility and the replaceable, may carry on the design and the manufacture according to the product demand. Through mold processing, can produce different shapes, sizes, materials and surface treatments of products to meet the personalized and customized needs of consumers. This flexibility and diversity for enterprises bring greater market competitiveness and business opportunities

5. Promoting the sustainable development of industry

Injection mold in industrial production promotes the sustainable development of industry, mold processing needs less materials and energy, reducing the consumption of natural resources. By optimizing the design and improving the process, we can reduce the generation of waste and pollutants and reduce the risk of environmental pollution. In addition, the mold has a long service life, can be recycled and re-manufactured, and reduces the generation of waste and treatment costs, to achieve sustainable use of resources.