In the dynamic landscape of industrial automation, plastic flexible chain spiral conveyors have emerged as a cutting-edge solution, revolutionizing material handling processes in factories. This article explores the definition, performance, advantages, disadvantages, applications, and future trends of these innovative conveyors.

Definition

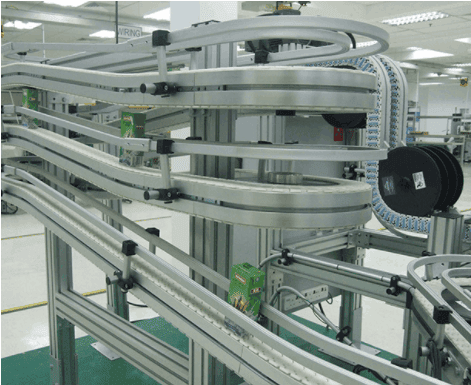

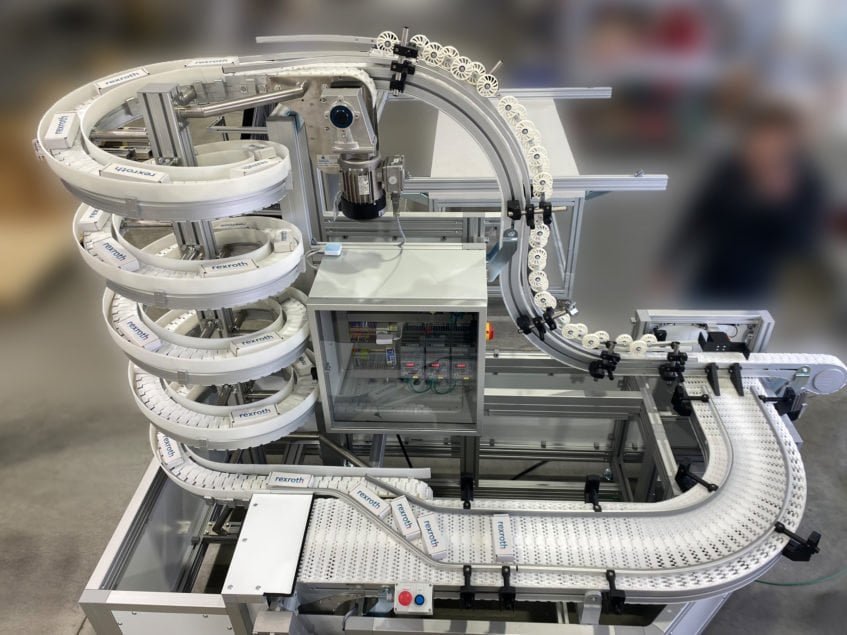

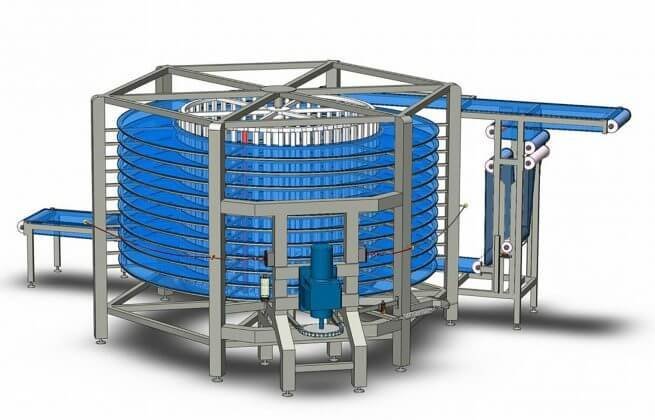

Plastic flexible chain spiral conveyors are a type of automated material handling system designed for vertical transportation of goods within a confined space. Unlike traditional conveyors, these systems utilize a flexible chain made of high-quality plastic, enabling smooth and efficient movement of products along a spiraling path.

Performance

The performance of plastic flexible chain spiral conveyors is marked by their precision, reliability, and adaptability. These conveyors can handle a wide range of products, from small components to larger items, with remarkable ease. The spiral design allows for a continuous flow of materials, minimizing downtime and optimizing production efficiency. Advanced control systems ensure accurate positioning and synchronization, contributing to overall operational excellence.

Advantages

- Space Efficiency: The vertical spiral design maximizes floor space utilization, making them ideal for facilities with limited room.

- Flexible Configurations: Plastic flexible chain conveyors can be customized to suit specific production requirements, offering versatility in layout and design.

- Gentle Product Handling: The plastic chain ensures gentle handling of products, reducing the risk of damage during transportation.

- Low Maintenance: These conveyors typically have fewer moving parts, leading to reduced maintenance requirements and increased reliability.

Disadvantages

- Initial Investment: The upfront cost of implementing plastic flexible chain spiral conveyors can be higher than traditional conveyor systems.

- Limited Load Capacity: While suitable for a wide range of products, there may be limitations on extremely heavy or bulky items.

Applications

- Plastic flexible chain spiral conveyors find applications across various industries, including but not limited to:

- Food and Beverage: Ideal for conveying packaged goods, bottles, and containers in food processing plants.

- Automotive: Efficient transportation of components and parts in automotive manufacturing.

- Pharmaceuticals: Suitable for the vertical movement of pharmaceutical products in cleanroom environments.

Future Trends

- The future of plastic flexible chain spiral conveyors is poised for advancements in technology, including:

- Integration with IoT: Conveyors with IoT capabilities for real-time monitoring and predictive maintenance.

- Enhanced Material Technologies: Continued development of advanced plastic materials for improved durability and performance.

- Increased Customization: Greater emphasis on tailoring conveyor systems to meet specific industry and application needs.

Conclusion

In conclusion, plastic flexible chain spiral conveyors represent a significant leap forward in automation equipment, offering unparalleled efficiency and adaptability. While they come with initial investment considerations, their long-term benefits and evolving technologies position them as a crucial component in the future of automated material handling.